In machining, the edge, Angle, edge and other parts of the workpiece will inevitably occur burrs of different sizes after cutting. The existence of burrs on the workpiece machining accuracy, installation accuracy, reprocessing positioning and appearance quality and many other aspects will form an adverse impact.

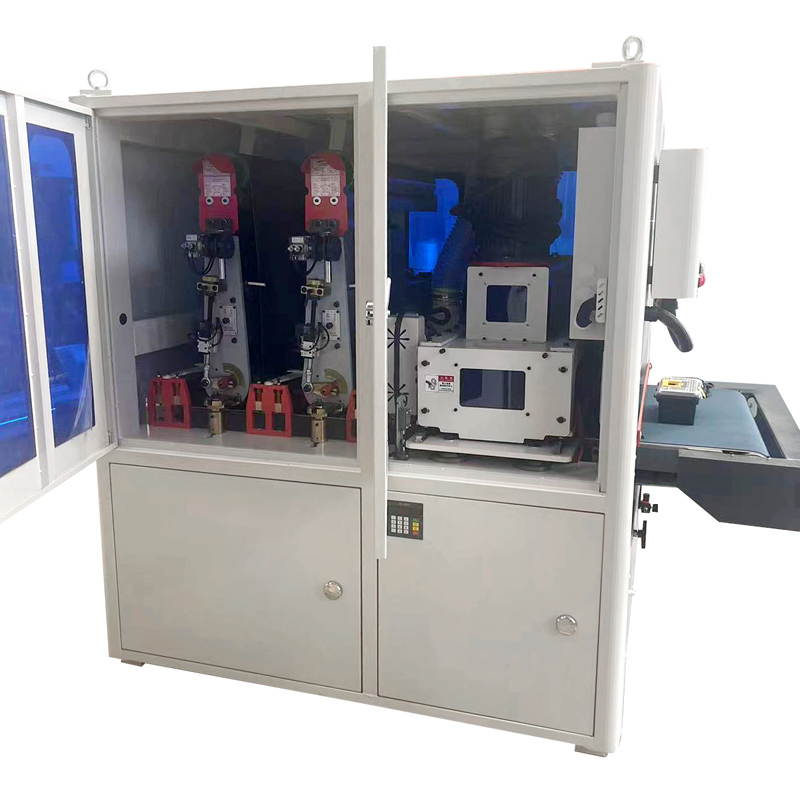

Deburring polishing equipment is used to remove burrs formed after processing of various parts and improve the finish to meet the requirements of metal, plastic and other parts.

Deburring machine is a kind of professional metal deburring equipment, using high-speed rotating nylon brush or wire brush to touch the workpiece for polishing and deburring, can remove the metal surface, inner hole, edge of the burr and flash, etc., to meet the requirements of high precision metal parts; The equipment is wet polished together, and the workpiece is cooled and cleaned by circulating cutting fluid system.

Working principle: The use of super strong electromagnetic force, conducting fine grinding stainless steel needle, high-speed activity, turning and other actions, in the workpiece hole, appearance conflict. Promote the efficient removal of workpiece burrs, and the role of cleaning and polishing.

Functions:

1, the workpiece inner hole removal burr fine grinding.

2. Removal of oxidized film.

3, oil stain product surface polishing treatment.

4, rust removal treatment.

5, sintering black marks processing.

6, gold jewelry industry grinding cleaning operations.

7, fine seams to remove burrs.